THE RIGHT TOOL MAKES ALL THE DIFFERENCE

FREYSSI FLAT JACKS

Temporary Flat Jacks • Permanent Flat Jacks • Complex Flat Jack Systems

Freyssi Flat Jacks, essential for civil and structural engineers, offer a practical solution for applications requiring controlled large forces. Used in both unforeseen challenges and new constructions, these jacks detail guidelines on bearing area, access gaps, tandem usage, shear resistance, and inlet/vent positioning. Operating at 150 bar, they ensure low bearing pressures, precise control, and versatility for various purposes, including structural lifting, underpinning, and seismic isolators. With advantages like known forces, low height, and adaptability, Freyssi Flat Jacks provide solutions for intricate engineering needs.

FREYSSI FLAT JACKS

General Description

Freyssi Flat Jacks are simple, practical devices for the civil or structural engineer wherever the application or control of large force heavy lifting is required. They are frequently used in the solution of unforeseen problems such as in remedial measures or structural additions. They are as often used in new constructions in which they form part of the structural concept.

In the years since their invention by Eugene Freyssinet in 1934, many techniques have been evolved for many applications:

Freyssi Flat Jack

Advantages of Freyssi Flat Jacks

- Known Forces

- Precise Control

- Low Height For Limited Access

- Low Bearing Stresses

- Out Of Parallel Tolerance

- Between Jacking Surfaces

- Temporary, Removable Jacks

- Permanent, Sacrificial Jacks

- Structural Lifting

- Underpinning

- Control Of Thrust Forces

- Maintenance Of ConstantThrust

- Adjustment Of Support Reactions

- Pretressing

- Structural Pre-Loading

- Loading Of Seismic Isolators

- Arch De-Centering

- Control Of Settlement

- Measurement Of Forces

- Weighing Of Offshore Structures

- Permanent Shimming

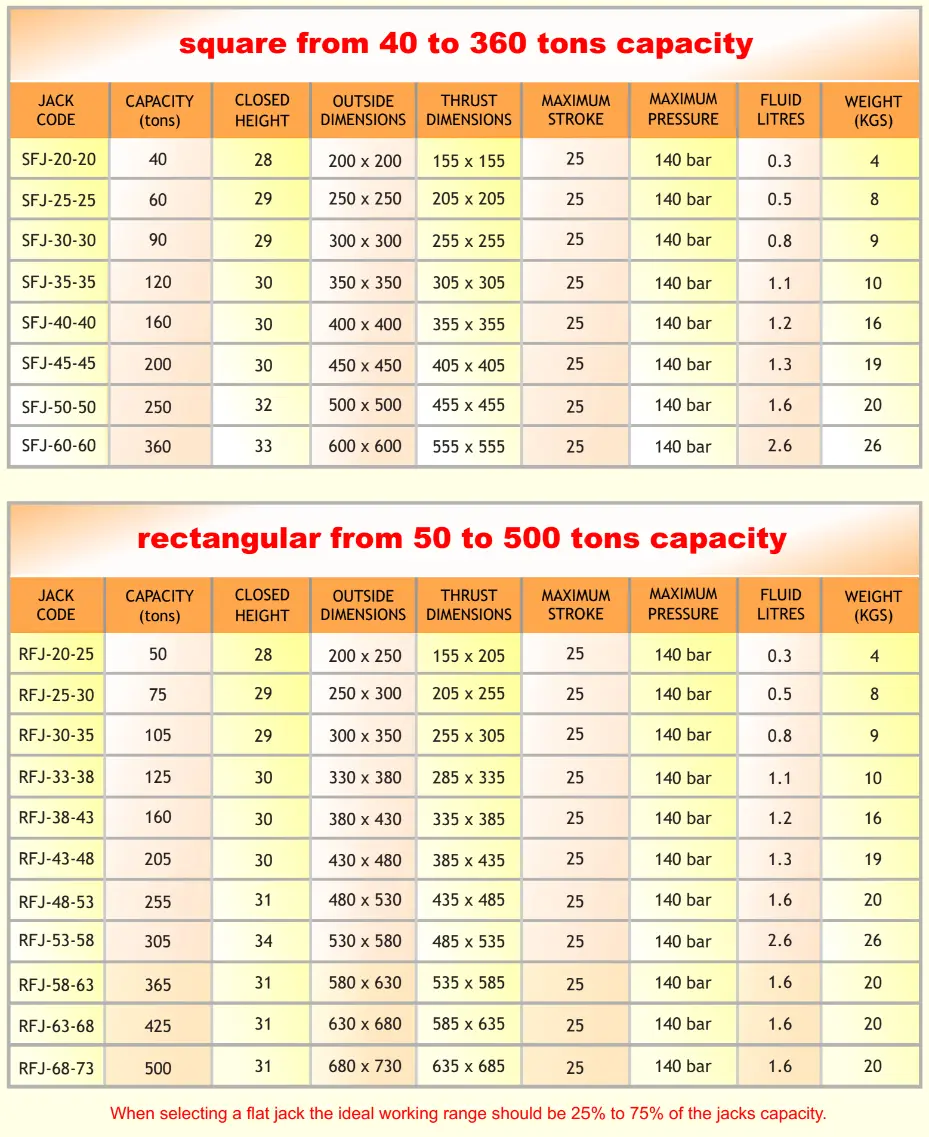

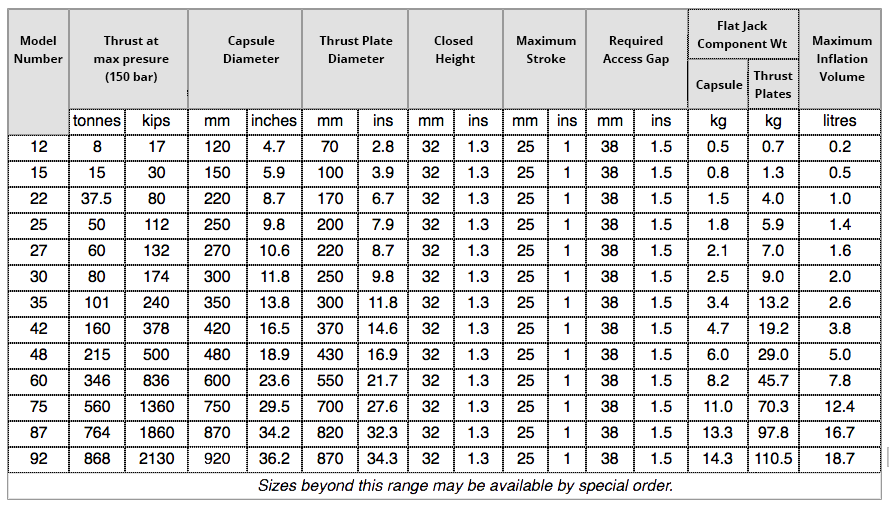

Freyssi Flat Jack Chart

Freyssi Flat Jack Detailing Guidlines

- Bearing Area – The whole surface of the flat jack thrust plate must bear upon a jacking surface. Local stiffening, distribution steel or concrete may be necessary.

- Access Gaps – The selection chart shows the thickness and minimum access gap requirements which must be provided. If the full travel of the jack is required then packing shims must be fitted to fill any remaining space before inflation.

- Tandem Jacks – Where the required jacking distance exceeds the travel of a single jack they may be stacked one on top of another and then inflated in sequence. Only the larger sizes of flat jacks may be stacked more than two high.

- Sheer Resistance – Flat jacks must not be subjected to shear loads. Where necessary the flat jack must be protected from shear forces by housing in a shear box or by another means.

- Inlet/Vent Positioning – Flat jacks can be made with suitable inlet positions where access is especially difficult.

- Oil-Resin Transfusion Jacks – When jacks are to be oil inflated and later transfused with epoxy resin, they are manufactured with an internal pipe to ensure satisfactory oil displacement. This requirement should be specified at the time of detailing.

- Safety Packs – It is frequently advisable to make provision for safety packs when temporary oil flat jacks are intended to be in position for extended periods and at risk from mechanical damage from other activities in the jacking area

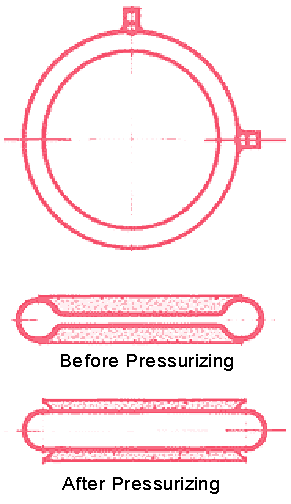

- The flat jack consists of a mild steel capsule, circular in plan, with a cross section that is initially dumb-bell shaped. The dished portions are fitted with ground steel thrust plates before the jack is placed between the surfaces to be jacked apart. When the jack is inflated with a liquid the hydrostatic pressure is transmitted by the flat portions of the capsule through the thrust plates while the toroidal rim of the flat jack deforms to allow the flat faces to move apart.

- The maximum operating pressure is only 150 bar (2,200psi). Flat jacks thereby exert low bearing pressures on the jacked faces.

- The maximum recommended opening stroke of a flat jack is equal to the depth of the toroidal rim – about 1in.

- Two pipe connections are welded into the jack rim usually at 90 degrees to one another. One provides the inlet for inflation and the other serves as a vent during filling and is subsequently capped off.

Calibrated Flat Jacks & Weighing

A flat jack which has been pre-opened, fitted with a pressure gauge or transducer, sealed and then calibrated in a press can be used as a robust, accurate load cell. This load cell can be placed in tandem with a standard flat jack of the same size.

The twin jacks are then installed beneath a structure at weighing positions. The weight of the structure taken by inflation of the standard flat jack registers a pressure in the calibrated flat jack which, by reference to its calibration graph, provides an accurate weight.

Using this principle, offshore structures ranging from modules of several hundred tonnes to complete integrated decks of over 30,000 tonnes to an accuracy of +/- 1%. Where necessary for lighter structures, an arrangement is available with greater accuracy.

Temporary Flat Jacks

Oil Inflation – When flat jacks are to be used for a limited period and subsequently removed inflation is usually done with hydraulic fluid. For small numbers of jacks, requiring relatively small volumes of oil, simple hand pumps may be used for inflation. Larger jacks or large numbers of jacks may require electric or diesel powered pumps.

Oil Inflation – When flat jacks are to be used for a limited period and subsequently removed inflation is usually done with hydraulic fluid. For small numbers of jacks, requiring relatively small volumes of oil, simple hand pumps may be used for inflation. Larger jacks or large numbers of jacks may require electric or diesel powered pumps.

Hydraulic Circuits – Single or multiple flat jacks can be inflated individually or on inter-connected circuits. Each jack has a needle valve for locking off and may be fitted with a pressure gauge if required.

Permanent Flat Jacks

Where a force is required to be permanently applied to a structure, flat jacks are inflated under pressure with an epoxy resin by means of a special resin injection cylinder. The epoxy resin hardens over a period of time to leave the force permanently applied. This type of application is suitable for pre-loading new or additional steelwork in structures, underpinning works and structural bearing installation.

This method is often used where sufficient room is not available for wedging or grouting the jacking gap.

In certain circumstances, it may be necessary to carry out the initial inflation on hydraulic oil with resin inflation being carried out at a later date. An oil to resin transfusion system is then required.

Complex Flat Jack Systems

In applications using multiple flat jacks the hydraulic pumping circuitry can be arranged appropriately using pipe and compression fitting or flexible hoses and quick release couplings.

In applications using multiple flat jacks the hydraulic pumping circuitry can be arranged appropriately using pipe and compression fitting or flexible hoses and quick release couplings.

Individual jacks are usually fitted with manual needle valves. Pressure gauges may be fitted to individual jacks, downstream of their needle valves, instead of or in addition to a common ring main gauge. Differing loads in neighboring jacks may thus be locked in and monitored as necessary.

For especially complex operations solenoid valves, electronic pressure transducers and computer control, monitoring and data logging systems may be used.

Calibrated Flat Jacks & Weighing A flat jack which has been pre-opened, fitted with a pressure gauge or transducer, sealed and then calibrated in a press can be used as a robust, accurate load cell. This load cell can be placed in tandem with a standard flat jack of the same size.

A flat jack which has been pre-opened, fitted with a pressure gauge or transducer, sealed and then calibrated in a press can be used as a robust, accurate load cell. This load cell can be placed in tandem with a standard flat jack of the same size.

The twin jacks are then installed beneath a structure at weighing positions. The weight of the structure taken by inflation of the standard flat jack registers a pressure in the calibrated flat jack which, by reference to its calibration graph, provides an accurate weight.

Using this principle, offshore structures ranging from modules of several hundred tonnes to complete integrated decks of over 30,000 tonnes to an accuracy of +/- 1%. Where necessary for lighter structures, an arrangement is available with greater accuracy.